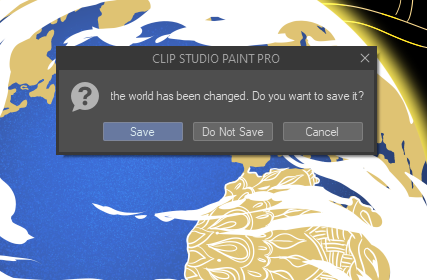

When Your Art Program’s Closing Message Hits You Straight In The Heart And Makes You Stop And Contemplate

when your art program’s closing message hits you straight in the heart and makes you stop and contemplate the state of it all

More Posts from Wolfspoot and Others

There are four types of fish scales!

Cycloid scales are thin, overlap, and flexible. They're found on primitive teleosts (like minnows and carp).

Ctenoid scales have small, backwards pointed scales (known as cterns) make the fish more hydrodynamic and faster. They're found on Advanced Ctenoids (like perch and sunfish).

Ganoid scales are thick, diamond-shaped, and mostly non-overlapping. They're found on Chondrostei (like sturgeons and paddlefish).

Placoid scales are spikey and tooth-like with nerves. These are found on Chondrichthyes (like sharks and rays).

Ichthyology Notes 3/?

good read for teachers.

I’ve been in such a funk since the concert. I’m not even sure I enjoyed myself that much. maybe I did. I don’t know

"Clothing tags, travel cards, hotel room key cards, parcel labels … a whole host of components in supply chains of everything from cars to clothes. What do they have in common? RFID tags.

Every RFID (Radio Frequency Identification) tag contains a microchip and a tiny metal strip of an antenna. A cool 18bn of these are made – and disposed of – each year. And with demands for product traceability increasing, ironically in part because of concerns for the social and environmental health of the supply chain, that’s set to soar.

And guess where most of these tags end up? Yup, landfill – adding to the burgeoning volumes of e-waste polluting our soils, rivers and skies. It’s a sorry tale, but it’s one in which two young graduates of Imperial College London and Royal College of Art are putting a great big green twist. Under the name of PulpaTronics, Chloe So and Barna Soma Biro reckon they’ve hit on a beguilingly simple sounding solution: make the tags out of paper. No plastic, no chips, no metal strips. Just paper, pure and … simple … ? Well, not quite, as we shall see.

The apparent simplicity is achieved by some pretty cutting-edge technical innovation, aimed at stripping away both the metal antennae and the chips. If you can get rid of those, as Biro explains, you solve the e-waste problem at a stroke. But getting rid of things isn’t the typical approach to technical solutions, he adds. “I read a paper in Nature that set out how humans have a bias for solving problems through addition – by adding something new, rather than removing complexity, even if that’s the best approach.”

And adding stuff to a world already stuffed, as it were, can create more problems than it solves. “So that became one of the guiding principles of PulpaTronics”, he says: stripping things down “to the bare minimum, where they are still functional, but have as low an environmental impact as possible”.

...how did they achieve this magical simplification? The answer lies in lasers: these turn the paper into a conductive material, Biro explains, printing a pattern on the surface that can be ‘read’ by a scanner, rather like a QR code. It sounds like frontier technology, but it works, and PulpaTronics have patents pending to protect it.

The resulting tag comes in two forms: in one, there is still a microchip, so that it can be read by existing scanners of the sort common within retailers, for example. The more advanced version does away with the chip altogether. This will need a different kind of scanner, currently in development, which PulpaTronics envisages issuing licences for others to manufacture.

Crucially, the cost of both versions is significantly cheaper than existing RFID kit – making this a highly viable proposition. Then there are the carbon savings: up to 70% for the chipless version – so a no-brainer from a sustainability viewpoint too. All the same, industry interest was slow to start with but when PulpaTronics won a coveted Dezeen magazine award in late 2023, it snowballed, says So. Big brands such as UPS, DHL, Marks & Spencer and Decathlon came calling. “We were just bombarded.” Brands were fascinated by the innovation, she says, but even more by the price point, “because, like any business, they knew that green products can’t come with a premium”."

-via Positive.News, April 29, 2024

--

Note: I know it's still in the very early stages, but this is such a relief to see in the context of the environmental and human rights bullshit associated with lithium mining, and the way that EVs and other green infrastructure are massively increasing the demand for rare metals.

I'll take a future with paper-based, more humane alternatives for sure! Fingers crossed this keeps developing and develops well (and quickly).

"The Netherlands is pulling even further ahead of its peers in the shift to a recycling-driven circular economy, new data shows.

According to the European Commission’s statistics office, 27.5% of the material resources used in the country come from recycled waste.

For context, Belgium is a distant second, with a “circularity rate” of 22.2%, while the EU average is 11.5% – a mere 0.8 percentage point increase from 2010.

“We are a frontrunner, but we have a very long way to go still, and we’re fully aware of that,” Martijn Tak, a policy advisor in the Dutch ministry of infrastructure and water management, tells The Progress Playbook.

The Netherlands aims to halve the use of primary abiotic raw materials by 2030 and run the economy entirely on recycled materials by 2050. Amsterdam, a pioneer of the “doughnut economics” concept, is behind much of the progress.

Why it matters

The world produces some 2 billion tonnes of municipal solid waste each year, and this could rise to 3.4 billion tonnes annually by 2050, according to the World Bank.

Landfills are already a major contributor to planet-heating greenhouse gases, and discarded trash takes a heavy toll on both biodiversity and human health.

“A circular economy is not the goal itself,” Tak says. “It’s a solution for societal issues like climate change, biodiversity loss, environmental pollution, and resource-security for the country.”

A fresh approach

While the Netherlands initially focused primarily on waste management, “we realised years ago that’s not good enough for a circular economy.”

In 2017, the state signed a “raw materials agreement” with municipalities, manufacturers, trade unions and environmental organisations to collaborate more closely on circular economy projects.

It followed that up with a national implementation programme, and in early 2023, published a roadmap to 2030, which includes specific targets for product groups like furniture and textiles. An English version was produced so that policymakers in other markets could learn from the Netherlands’ experiences, Tak says.

The programme is focused on reducing the volume of materials used throughout the economy partly by enhancing efficiencies, substituting raw materials for bio-based and recycled ones, extending the lifetimes of products wherever possible, and recycling.

It also aims to factor environmental damage into product prices, require a certain percentage of second-hand materials in the manufacturing process, and promote design methods that extend the lifetimes of products by making them easier to repair.

There’s also an element of subsidisation, including funding for “circular craft centres and repair cafés”.

This idea is already in play. In Amsterdam, a repair centre run by refugees, and backed by the city and outdoor clothing brand Patagonia, is helping big brands breathe new life into old clothes.

Meanwhile, government ministries aim to aid progress by prioritising the procurement of recycled or recyclable electrical equipment and construction materials, for instance.

State support is critical to levelling the playing field, analysts say...

Long Road Ahead

The government also wants manufacturers – including clothing and beverages companies – to take full responsibility for products discarded by consumers.

“Producer responsibility for textiles is already in place, but it’s work in progress to fully implement it,” Tak says.

And the household waste collection process remains a challenge considering that small city apartments aren’t conducive to having multiple bins, and sparsely populated rural areas are tougher to service.

“Getting the collection system right is a challenge, but again, it’s work in progress.”

...Nevertheless, Tak says wealthy countries should be leading the way towards a fully circular economy as they’re historically the biggest consumers of natural resources."

-via The Progress Playbook, December 13, 2023

Something that I think should be an important part of solarpunk aesthetics is screws.

Look at your smartphone. No screws. You've got to have specialized tools to get inside your phone to repair something. There are certain pieces of tech that are glued in place and glue can't be undone without permanently breaking the bond.

But screws!

You can take apart a broken old radio, repair what's broken, and, if you were careful in taking it apart, you can put it back together and have a fully functioning radio and all you need is a common screwdriver!

It's hard to build screws and other mechanical fasteners because it requires more planning than clamps and glues, but isn't that what solarpunk is all about‽ It's about care and sustainability and and a radio or a computer built carefully with repair in mind is a sustainable computer that stays out of landfills and in use.

-

randomwatcher72 reblogged this · 4 weeks ago

randomwatcher72 reblogged this · 4 weeks ago -

sorry-frank reblogged this · 4 weeks ago

sorry-frank reblogged this · 4 weeks ago -

le-random-yeet-up reblogged this · 4 weeks ago

le-random-yeet-up reblogged this · 4 weeks ago -

sourweather reblogged this · 4 weeks ago

sourweather reblogged this · 4 weeks ago -

ketchupkio reblogged this · 4 weeks ago

ketchupkio reblogged this · 4 weeks ago -

nykenima liked this · 4 weeks ago

nykenima liked this · 4 weeks ago -

louie-the-v reblogged this · 4 weeks ago

louie-the-v reblogged this · 4 weeks ago -

kazerbeam3 reblogged this · 4 weeks ago

kazerbeam3 reblogged this · 4 weeks ago -

kazerbeam3 liked this · 4 weeks ago

kazerbeam3 liked this · 4 weeks ago -

hobics liked this · 4 weeks ago

hobics liked this · 4 weeks ago -

lichengender reblogged this · 4 weeks ago

lichengender reblogged this · 4 weeks ago -

sirquacklesdefoof liked this · 4 weeks ago

sirquacklesdefoof liked this · 4 weeks ago -

ahsadler reblogged this · 4 weeks ago

ahsadler reblogged this · 4 weeks ago -

bookantique reblogged this · 4 weeks ago

bookantique reblogged this · 4 weeks ago -

mrowsters reblogged this · 4 weeks ago

mrowsters reblogged this · 4 weeks ago -

yaboiii-azzy reblogged this · 4 weeks ago

yaboiii-azzy reblogged this · 4 weeks ago -

yaboiii-azzy liked this · 4 weeks ago

yaboiii-azzy liked this · 4 weeks ago -

duesterplush reblogged this · 4 weeks ago

duesterplush reblogged this · 4 weeks ago -

duesterplush liked this · 4 weeks ago

duesterplush liked this · 4 weeks ago -

svevelyn liked this · 4 weeks ago

svevelyn liked this · 4 weeks ago -

lunesartsworld reblogged this · 4 weeks ago

lunesartsworld reblogged this · 4 weeks ago -

serenefreakgeek reblogged this · 4 weeks ago

serenefreakgeek reblogged this · 4 weeks ago -

lunesartsworld liked this · 4 weeks ago

lunesartsworld liked this · 4 weeks ago -

jambettina liked this · 4 weeks ago

jambettina liked this · 4 weeks ago -

thehorridgibon liked this · 4 weeks ago

thehorridgibon liked this · 4 weeks ago -

samantha-kirkland reblogged this · 4 weeks ago

samantha-kirkland reblogged this · 4 weeks ago -

thaemin reblogged this · 4 weeks ago

thaemin reblogged this · 4 weeks ago -

rageandglitter reblogged this · 4 weeks ago

rageandglitter reblogged this · 4 weeks ago -

adustbaginturmoil reblogged this · 4 weeks ago

adustbaginturmoil reblogged this · 4 weeks ago -

chihuahuarocks reblogged this · 4 weeks ago

chihuahuarocks reblogged this · 4 weeks ago -

foooxobsessedperson reblogged this · 4 weeks ago

foooxobsessedperson reblogged this · 4 weeks ago -

zecon125 liked this · 4 weeks ago

zecon125 liked this · 4 weeks ago -

havenwitchworks reblogged this · 4 weeks ago

havenwitchworks reblogged this · 4 weeks ago -

pablolepuggo reblogged this · 4 weeks ago

pablolepuggo reblogged this · 4 weeks ago -

betterlivingindustriesss liked this · 4 weeks ago

betterlivingindustriesss liked this · 4 weeks ago -

golden-study-universe reblogged this · 4 weeks ago

golden-study-universe reblogged this · 4 weeks ago -

justiebunch liked this · 4 weeks ago

justiebunch liked this · 4 weeks ago -

beansplat liked this · 4 weeks ago

beansplat liked this · 4 weeks ago -

wdcasey1895 reblogged this · 4 weeks ago

wdcasey1895 reblogged this · 4 weeks ago -

thatfluffypuff reblogged this · 4 weeks ago

thatfluffypuff reblogged this · 4 weeks ago -

daemonophobic liked this · 4 weeks ago

daemonophobic liked this · 4 weeks ago -

dragonflylover545 reblogged this · 4 weeks ago

dragonflylover545 reblogged this · 4 weeks ago -

tinynavajo reblogged this · 4 weeks ago

tinynavajo reblogged this · 4 weeks ago -

iris-of-mooonlight reblogged this · 4 weeks ago

iris-of-mooonlight reblogged this · 4 weeks ago -

imnotdantee liked this · 4 weeks ago

imnotdantee liked this · 4 weeks ago -

queen-of-wyrms liked this · 4 weeks ago

queen-of-wyrms liked this · 4 weeks ago -

man-i-dunno reblogged this · 4 weeks ago

man-i-dunno reblogged this · 4 weeks ago -

omegabeast27 reblogged this · 4 weeks ago

omegabeast27 reblogged this · 4 weeks ago -

thebadgerhastheanswer reblogged this · 4 weeks ago

thebadgerhastheanswer reblogged this · 4 weeks ago -

amazingspider-z reblogged this · 4 weeks ago

amazingspider-z reblogged this · 4 weeks ago

I’m a young-adult woman with the hopes of becoming a well-known writer. I’m a dreamer, a music lover and a chaotic human being, curious about what the future will bring but without any idea of what to do with it. As for this tumblr, we’ll see. I will make an attempt to make an interesting place but for now I still have to figure out what to do with it.

167 posts