Sieveplayer - Sieve's

More Posts from Sieveplayer and Others

Map of my current fantasy world, Theia. The one on the top is an updated version of the map with some improved borders, bottom is a more outdated version of the map, but with accompanying lore, though I'll fully update everything in the future. Main premise is that the world is undergoing a cold war between major mago-industrial powers with one story I'm working on taking place within the Io Consortium, which is an unstable megacorporate state being fought over by the Demonic Confederacy and the Avalonian Empire.

you heard him

Civic Nationalism

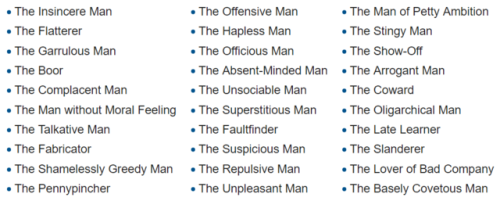

I'm the Late Learner

i found a list of stock characters in ancient greek media

tag yourself i’m the man of petty ambition

In space no one can hear you genocide.

137 Hours on Stellaris

(via qualitysteamreviews)

me (decorated in bloody runes): man why did we ever stop worshipping golden idols this shit rules

severed bull’s head i carry with me for advice: if you mix sulfur, charcoal, and saltpeter together you will become a powerful sorcerer

Hide and Seek

"Demo man is not a real man, he is only a man in spirit"

I think a lot about manufacturing processes because they’re the most impressive things humanity has ever done and injection moulding wacks me out the most. I was looking at the toy keyboard I bought a while back and it got me thinking about how much of what we consider to be the look of The Modern Era is down to injection moulding.

I hold that injection moulding is one of the pillars of modern society and technology. Can you imagine a world where you couldn’t use injection moulding. It’d look completely foreign. Like looking into an alien world. When you consider it you have to conclude that injection moulding has shaped our culture as much as the development of the camera or the invention of the piano or the creation of glassblowing. If archaeologists had to name our culture in the style of the Corded Ware culture or the Funnel Beaker culture, we’d be the Injection Moulded Plastic culture.

Injection moulding is how we get, oh, almost every plastic thing you’ve ever seen. The keys on your keyboard are injection moulded. Your phone case is injection moulded. Unless you’ve got a fancy milled metal laptop like a macbook then your laptop’s chassis is mostly injection moulded plastic. Your lightswitches are injection moulded. Plastic water bottles are injection moulded. Injection moulding is how we can produce extremely similar objects at breakneck pace for almost no money.

Now it’s important to rememeber that injection moulding isn’t cheap, or, well, injection moulding is only cheap for mass production. Every single unique piece of plastic needs a mould, and each mould will cost somewhere around thousands to tens of thousands of dollars EACH, depending on how tight the tolerances are and how complex the geometry is. Look at how many unique plastic pieces there are on that keyboard. Each one represents an investment of like $7000 into making this toy that gets sold for about $20, so there’s no way this would get made unless the company had plans to sell literally hundreds of thousands of these things.

(This mould can spit out one chair every 30 seconds and it probably cost twenty thousand dollars to make)

Once you learn to see injection moulding you can’t unsee it. It’s like learning about kerning, or musical intervals, or disability compliant designs, or the pantone colours, or about how many insulator disks are needed on different voltage power lines. You start to see it everywhere, you realise that everything in your life relies upon our ability to jam plastic through a heated screw and into a mould reliably, hundreds of times per day, all day, every day.

Unless you’re wandering alone in the wilderness (and even then, maybe: check your clothing), look around and see if there’s something injection moulded near you. I can tell you the answer, there definitely is. It’s inescapable.

What would a world without injection moulded parts look like? It’d be weird. Everything we think of as cheap and easy to make is suddenly expensive. Complex curves and slopes like you’d find on a one dollar potato peeler now require hours of work to form. Every budget consumer item would be like those cheap sheet metal PC cases that have drawn blood from everyone who build a PC in them. Everything now has the aesthetics of a Sun 3/280 system:

Heck, even this sheet steel cube has a dozen injection moulded parts visible.

All the chunky plastic housing of the 90′s and 2000′s, all the sleek curves of the 2010′s, all the cheap plastic knick-knacks, the plastic toy horses, the snugly-fitting appliance chassis, the stacking plastic chairs. All these things now cost ten times as much and have to be formed from heavy steel, or milled out of chunks of cast plastic, or replaced with formed sheet metal.

Our culture, artistic sensibilities, and sense of value has been irrevocably shaped by our ability to squeeze liquid plastic into a metal die.

-

lochsreblogs reblogged this · 2 weeks ago

lochsreblogs reblogged this · 2 weeks ago -

silwer999 reblogged this · 2 weeks ago

silwer999 reblogged this · 2 weeks ago -

nezjazz reblogged this · 2 weeks ago

nezjazz reblogged this · 2 weeks ago -

ryeallytired reblogged this · 2 weeks ago

ryeallytired reblogged this · 2 weeks ago -

alienembers reblogged this · 2 weeks ago

alienembers reblogged this · 2 weeks ago -

secretevillustrator liked this · 3 weeks ago

secretevillustrator liked this · 3 weeks ago -

demon-of-punk liked this · 3 weeks ago

demon-of-punk liked this · 3 weeks ago -

ultravioletsodapop liked this · 3 weeks ago

ultravioletsodapop liked this · 3 weeks ago -

inkyoctopunz liked this · 3 weeks ago

inkyoctopunz liked this · 3 weeks ago -

spongewinx reblogged this · 3 weeks ago

spongewinx reblogged this · 3 weeks ago -

spongewinx liked this · 3 weeks ago

spongewinx liked this · 3 weeks ago -

andromeda-gay reblogged this · 3 weeks ago

andromeda-gay reblogged this · 3 weeks ago -

slainbanjos reblogged this · 3 weeks ago

slainbanjos reblogged this · 3 weeks ago -

bizarrebirds reblogged this · 3 weeks ago

bizarrebirds reblogged this · 3 weeks ago -

bigtittymegatron reblogged this · 3 weeks ago

bigtittymegatron reblogged this · 3 weeks ago -

bigtittymegatron liked this · 3 weeks ago

bigtittymegatron liked this · 3 weeks ago -

icypolargirl78 reblogged this · 3 weeks ago

icypolargirl78 reblogged this · 3 weeks ago -

wistsandmagic reblogged this · 3 weeks ago

wistsandmagic reblogged this · 3 weeks ago -

basically reblogged this · 3 weeks ago

basically reblogged this · 3 weeks ago -

obieros reblogged this · 3 weeks ago

obieros reblogged this · 3 weeks ago -

point-of-void reblogged this · 3 weeks ago

point-of-void reblogged this · 3 weeks ago -

point-of-void liked this · 3 weeks ago

point-of-void liked this · 3 weeks ago -

luciferius-legion liked this · 3 weeks ago

luciferius-legion liked this · 3 weeks ago -

kjnumber4 liked this · 3 weeks ago

kjnumber4 liked this · 3 weeks ago -

baygeethefirst reblogged this · 3 weeks ago

baygeethefirst reblogged this · 3 weeks ago -

i-fear-neither-death-nor-pain reblogged this · 3 weeks ago

i-fear-neither-death-nor-pain reblogged this · 3 weeks ago -

berosar reblogged this · 4 weeks ago

berosar reblogged this · 4 weeks ago -

razerathane reblogged this · 1 month ago

razerathane reblogged this · 1 month ago -

jack-of-all-blades liked this · 1 month ago

jack-of-all-blades liked this · 1 month ago -

knightoftableround liked this · 1 month ago

knightoftableround liked this · 1 month ago -

00ff00dreams reblogged this · 1 month ago

00ff00dreams reblogged this · 1 month ago -

cobalt-sugar-punch reblogged this · 1 month ago

cobalt-sugar-punch reblogged this · 1 month ago -

cobalt-sugar-punch liked this · 1 month ago

cobalt-sugar-punch liked this · 1 month ago -

miloone liked this · 1 month ago

miloone liked this · 1 month ago -

thymetraveler reblogged this · 1 month ago

thymetraveler reblogged this · 1 month ago -

renslice liked this · 1 month ago

renslice liked this · 1 month ago -

inneryouthfart liked this · 1 month ago

inneryouthfart liked this · 1 month ago -

divine-regret-index-j liked this · 1 month ago

divine-regret-index-j liked this · 1 month ago -

nasuadatowers-blog liked this · 1 month ago

nasuadatowers-blog liked this · 1 month ago -

nythracwn-archive reblogged this · 1 month ago

nythracwn-archive reblogged this · 1 month ago -

my-little-enby-shop liked this · 1 month ago

my-little-enby-shop liked this · 1 month ago -

j-insomniac reblogged this · 1 month ago

j-insomniac reblogged this · 1 month ago -

j-insomniac liked this · 1 month ago

j-insomniac liked this · 1 month ago -

tired-and-unjellied reblogged this · 1 month ago

tired-and-unjellied reblogged this · 1 month ago -

anarchivalsystem reblogged this · 1 month ago

anarchivalsystem reblogged this · 1 month ago -

themechanicsnightmare liked this · 1 month ago

themechanicsnightmare liked this · 1 month ago -

jayla-king liked this · 1 month ago

jayla-king liked this · 1 month ago -

jesterpanic reblogged this · 1 month ago

jesterpanic reblogged this · 1 month ago